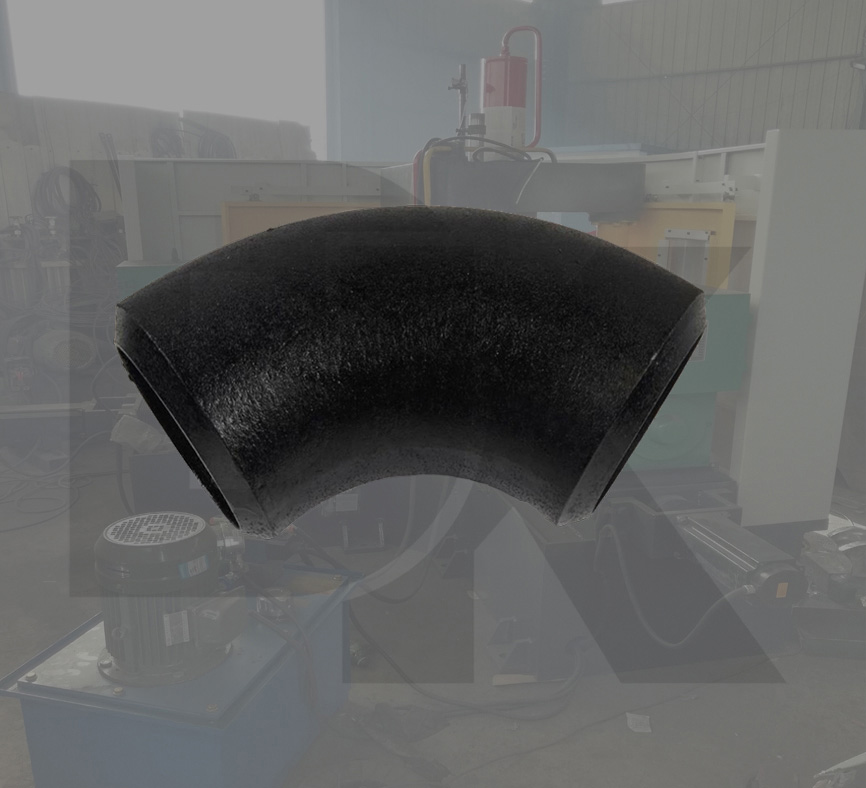

product description

The materials of butt welding elbows are carbon steel and carbon-manganese steel seamless steel pipes, and other materials can also be selected according to user requirements.

The materials of butt-welding elbows shall have quality certificates, and shall be fully re-inspected according to the requirements of relevant standards and specifications, and can be used only after they are qualified.

When ordering, both parties negotiate to increase the inspection items for materials, such as ultrasonic, penetration, magnetic particle inspection or other inspection items.

The inner and outer surfaces of butt welding elbows should be derusted and coated with anti-rust oil.

In principle, the butt welding elbows that pass the inspection are not subjected to the pressure test, but it should be ensured that all reducing joints can pass the water pressure test in the system.

Inspection

The butt welding elbow shall not have cracks, over-burning and other lack of fillings that impair the strength and appearance, and the inner and outer surfaces shall be smooth without oxide skin.

The structure size and limit deviation of butt welding elbow shall be implemented according to the requirements of ±12.5%.

Sampling inspection of butt welding elbows shall be carried out by ultrasonic or magnetic particle inspection.

| Gr W(kgs) | 45ºELBOWS LONG RADIUS | 90ºELBOWS LONG RADIUS | |||||||||||||

| DN | NPS | STD | S40 | XS | S80 | S120 | S160 | XXS | STD | S40 | XS | S80 | S120 | S160 | XXS |

| DN15 | ½" | 0.04 | 0.04 | 0.05 | 0.05 | 0.06 | 0.08 | 0.08 | 0.08 | 0.1 | 0.1 | 0.12 | 0.16 | ||

| DN20 | ¾" | 0.05 | 0.05 | 0.07 | 0.07 | 0.08 | 0.11 | 0.11 | 0.11 | 0.13 | 0.13 | 0.18 | 0.22 | ||

| DN25 | 1" | 0.08 | 0.08 | 0.09 | 0.09 | 0.13 | 0.16 | 0.15 | 0.15 | 0.19 | 0.19 | 0.26 | 0.33 | ||

| DN32 | 1¼" | 0.13 | 0.13 | 0.17 | 0.17 | 0.22 | 0.29 | 0.26 | 0.26 | 0.34 | 0.34 | 0.43 | 0.58 | ||

| DN40 | 1½" | 0.18 | 0.18 | 0.24 | 0.24 | 0.33 | 0.43 | 0.37 | 0.37 | 0.48 | 0.48 | 0.65 | 0.86 | ||

| DN50 | 2" | 0.33 | 0.33 | 0.44 | 0.44 | 0.67 | 0.81 | 0.65 | 0.65 | 0.88 | 0.88 | 1.33 | 1.81 | ||

| DN65 | 2½" | 0.68 | 0.68 | 0.88 | 0.88 | 1.17 | 1.52 | 1.35 | 1.35 | 1.75 | 1.75 | 2.33 | 3.05 | ||

| DN80 | 3" | 1 | 1 | 1.35 | 1.35 | 1.92 | 2.34 | 2.01 | 2.01 | 2.69 | 2.69 | 3.84 | 4.69 | ||

| DN90 | 3½" | 1.4 | 1.4 | 1.92 | 1.92 | 2.79 | 2.79 | 3.84 | 3.84 | ||||||

| DN100 | 4" | 1.9 | 1.9 | 2.64 | 2.64 | 3.39 | 4.03 | 4.9 | 3.8 | 3.8 | 5.27 | 5.27 | 6.77 | 8.05 | 9.81 |

| DN125 | 5" | 3.21 | 3.21 | 4.49 | 4.49 | 6 | 7.3 | 8.6 | 6.42 | 6.42 | 8.98 | 8.98 | 12 | 14.5 | 17.2 |

| DN150 | 6" | 4.93 | 4.93 | 7.4 | 7.4 | 9.7 | 11.8 | 14.2 | 9.85 | 9.85 | 14.8 | 14.8 | 19.4 | 23.6 | 28.4 |

| DN200 | 8" | 10.5 | 10.5 | 15.1 | 15.1 | 21.6 | 26.3 | 25.8 | 21 | 21 | 30.1 | 30.1 | 43.3 | 52.5 | 51.6 |

| DN250 | 10" | 18.1 | 18.1 | 23.9 | 28.5 | 39.8 | 50.5 | 46.4 | 36.1 | 36.1 | 47.8 | 57.1 | 79.5 | 101 | 92.7 |

| DN300 | 12" | 25.8 | 28.4 | 34.3 | 46.3 | 67 | 84 | 67 | 51.6 | 56.8 | 68.5 | 92.5 | 134 | 168 | 134 |

| DN350 | 14" | 34.1 | 39.8 | 44.9 | 66 | 94 | 116 | 68.2 | 79.1 | 89.8 | 132 | 188 | 236 | ||

| DN400 | 16" | 44.7 | 59 | 58 | 96.5 | 137 | 171 | 89.4 | 118 | 118 | 193 | 274 | 342 | ||

| DN450 | 18" | 56.5 | 84 | 75 | 137 | 196 | 247 | 113 | 168 | 150 | 274 | 391 | 494 | ||

| DN500 | 20" | 70 | 93 | 186 | 264 | 338 | 140 | 219 | 186 | 372 | 527 | 676 | |||

| DN550 | 22" | 84.5 | 113 | 246 | 347 | 450 | 169 | 225 | 491 | 695 | 899 | ||||

| DN600 | 24" | 101 | 135 | 317 | 460 | 580 | 202 | 366 | 269 | 634 | 920 | 1160 | |||

| DN650 | 26" | 119 | 158 | 237 | 316 | ||||||||||

| DN700 | 28" | 137 | 183 | 275 | 367 | ||||||||||

| DN750 | 30" | 159 | 211 | 317 | 421 | ||||||||||

| DN800 | 32" | 180 | 240 | 360 | 658 | 480 | |||||||||

| DN850 | 34" | 203 | 271 | 407 | 741 | 524 | |||||||||

| DN900 | 36" | 229 | 304 | 457 | 905 | 608 | |||||||||

Add.: Cangzhou City, Hebei Province, China

Tel.: +86 317 8969 768

Mob.: +86 186 3076 4242

Fax: +86 317 8969 768

WhatsApp: +86 186 3076 4242

WeChat: +86 186 3076 4242

Skype: live:manager_11748

E-mail: manager@tyfittingsmachine.com

NAVIGATION