product description

Production of pipe fittings involves mainly pressure processing.

In addition, there are welding, heat treatment, cutting, non-destructive testing, surface treatment, etc. The pressure process of pipe fittings is also the forming process of pipe.

Pressure process is also the forming of pipe fittings, which is mainly based on the plastic deformation characteristics of metal materials. The process can be roughly divided into hot processing and cold processing.

The process can be roughly divided into two ways, in these two ways can be divided into different pressure process.

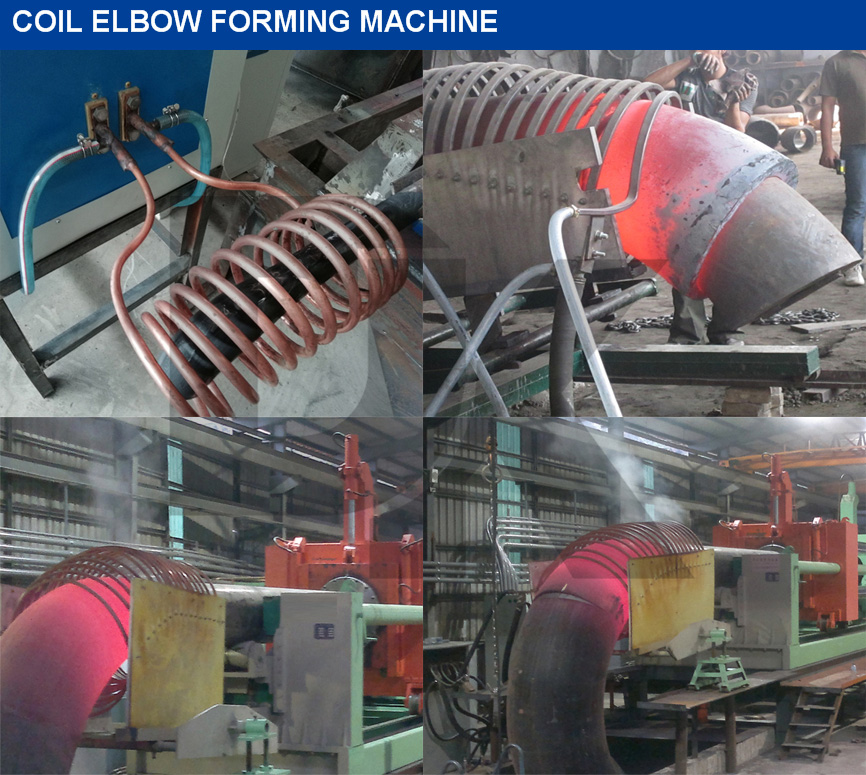

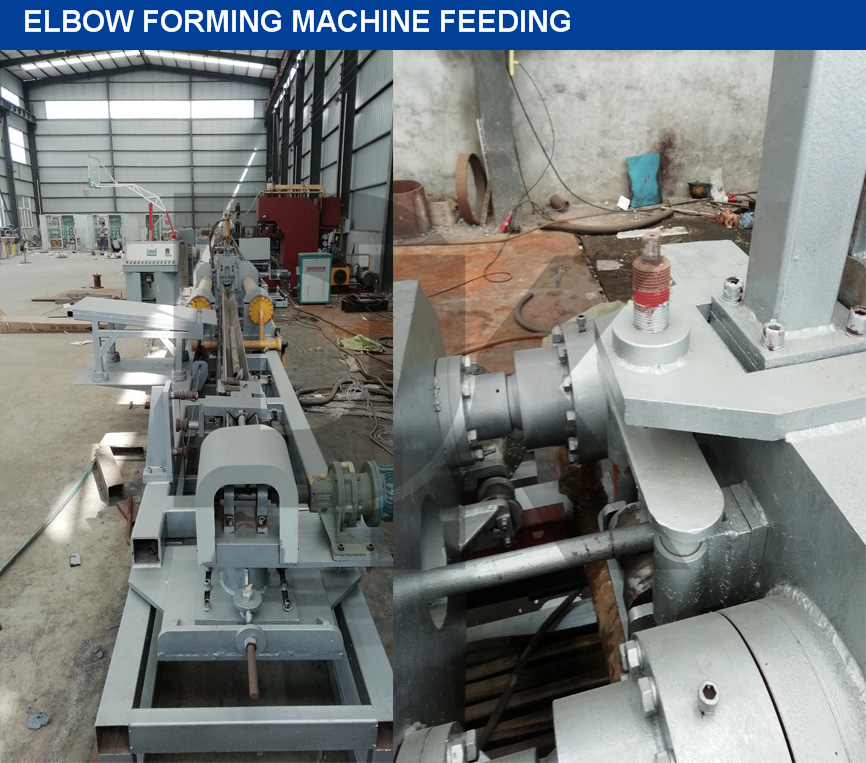

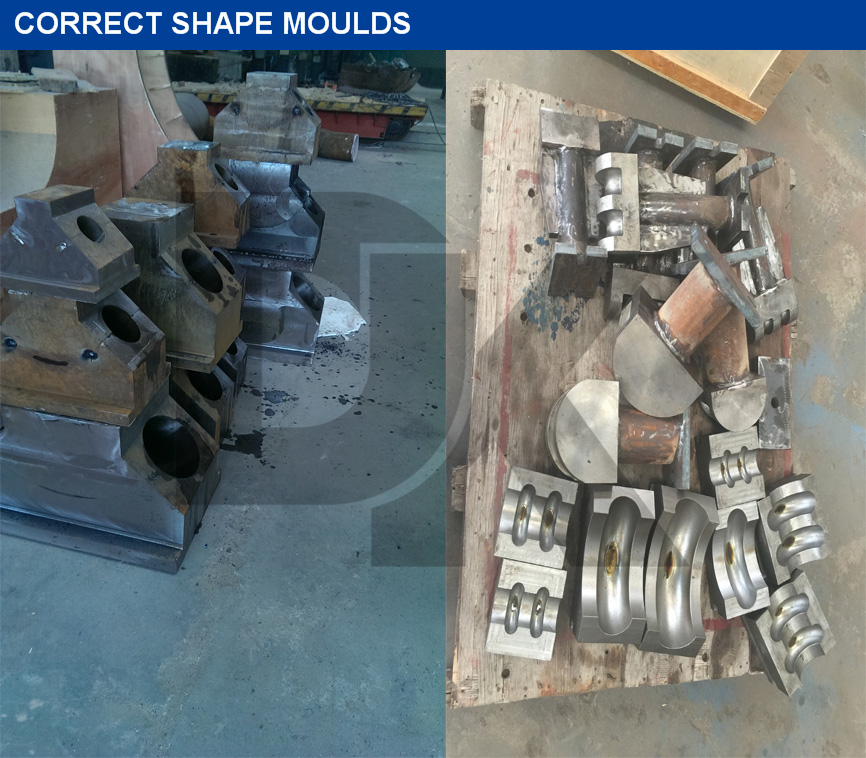

For example, commonly used specifications of the carbon steel elbow is usually used to expand the hot push process, low carbon steel materials (normally used) (A53, A106 B) in the heating to a certain temperature still has a certain degree of steel and good toughness, in the expansion of the bending deformation process is not easy to produce defects, with a high yield; the use of equipment for the special elbow pushing machine, there are Factory specializing in the production of such equipment; hot push elbow manufacturing technology in China has more than 30 years of history, manufacturing equipment has been relatively The manufacturing technology of hot-push elbow has a history of more than 30 years in China, the manufacturing equipment has been relatively perfect, the heating method has been improved, and the manufacturing level of mandrel has been greatly improved; carbon steel elbow using hot-push manufacturing process can be continuously produced to adapt the product.

Carbon steel elbow can be produced continuously by using the heat push manufacturing process, which can adapt to the characteristics of the large batch of the product, and can eliminate the subsequent heat treatment process, reducing the energy The heat push manufacturing process of carbon steel elbow can be continuously produced, which can adapt to the characteristics of large batch size of the product, and can eliminate the subsequent heat treatment process, reducing energy consumption and cost.

| NO. | Model | Elbow Range (mm) | Bending Radius | Thrust (t) | Bending Angle | M.F Power (kw) | Max Working Thrust (t) |

| 1 | DK-EW-114 | 25~114 | 1~2.5D | 50 | 0~135º | 160~200 | 42 |

| 2 | DK -EW-219 | 108~219 | 1~2.5D | 84 | 0~135º | 200~250 | 72 |

| 3 | DK -EW-325 | 108~325 | 1~2.5D | 106 | 0~135º | 300~350 | 91 |

| 4 | DK -EW-426 | 159~426 | 1~2.5D | 160 | 0~135º | 350~400 | 137 |

| 5 | DK -EW-558 | 219~530 | 1~2.5D | 206 | 0~135º | 400~450 | 177 |

| 6 | DK -EW-630 | 325~630 | 1~2.5D | 260 | 0~135º | 450~500 | 220 |

| 7 | DK -EW-720 | 325~720 | 1~2.5D | 300 | 0~135º | 500~600 | 257 |

| 8 | DK -EW-820 | 426~820 | 1~2.5D | 330 | 0~135º | 600~800 | 282 |

| 9 | DK -EW-914 | 426~914 | 1~2.5D | 410 | 0~135º | 600~800 | 351 |

| 10 | DK -EW-1067 | 530~1020 | 1~2.5D | 670 | 0~135º | 1000~1200 | 574 |

| 11 | DK -EW-1220 | 630~1220 | 1~2.5D | 850 | 0~135º | 1000~1200 | 728 |

| 12 | DK-EW-1420 | 720~1420 | 1~2.5D | 1050 | 0~135º | 1200~1500 | 900 |

| Note:1. The machine's technical parameters is based on pipe wall thickness≤20mm. | |||||||

| 2. MAX pipe wall thickness can be 150mm. Machine can be designed according to user's requirements. | |||||||

Add.: Cangzhou City, Hebei Province, China

Tel.: +86 317 8969 768

Mob.: +86 186 3076 4242

Fax: +86 317 8969 768

WhatsApp: +86 186 3076 4242

WeChat: +86 186 3076 4242

Skype: live:manager_11748

E-mail: manager@tyfittingsmachine.com

NAVIGATION