product description

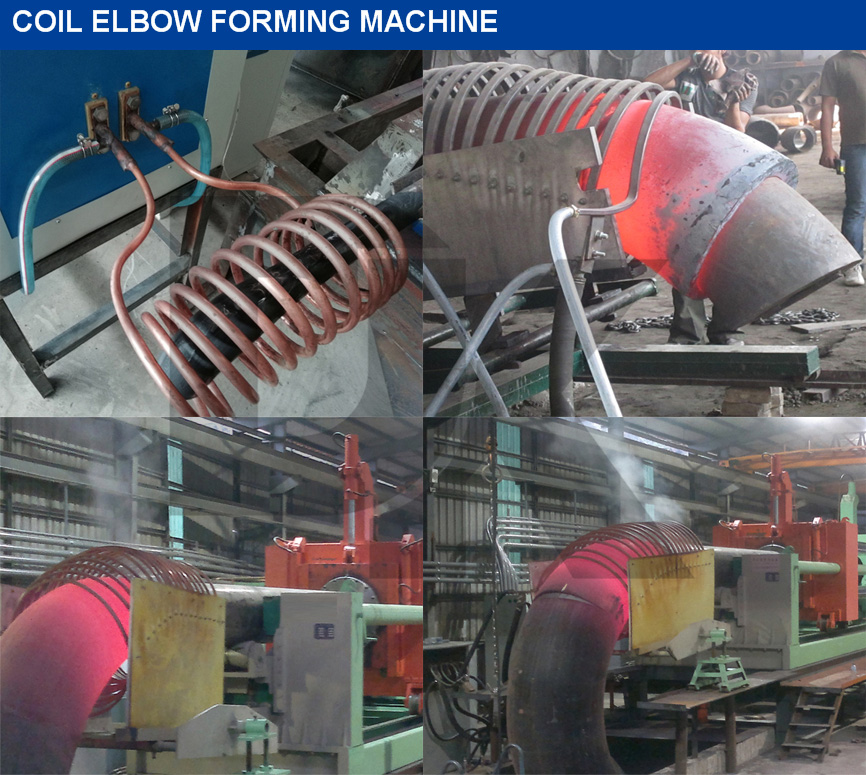

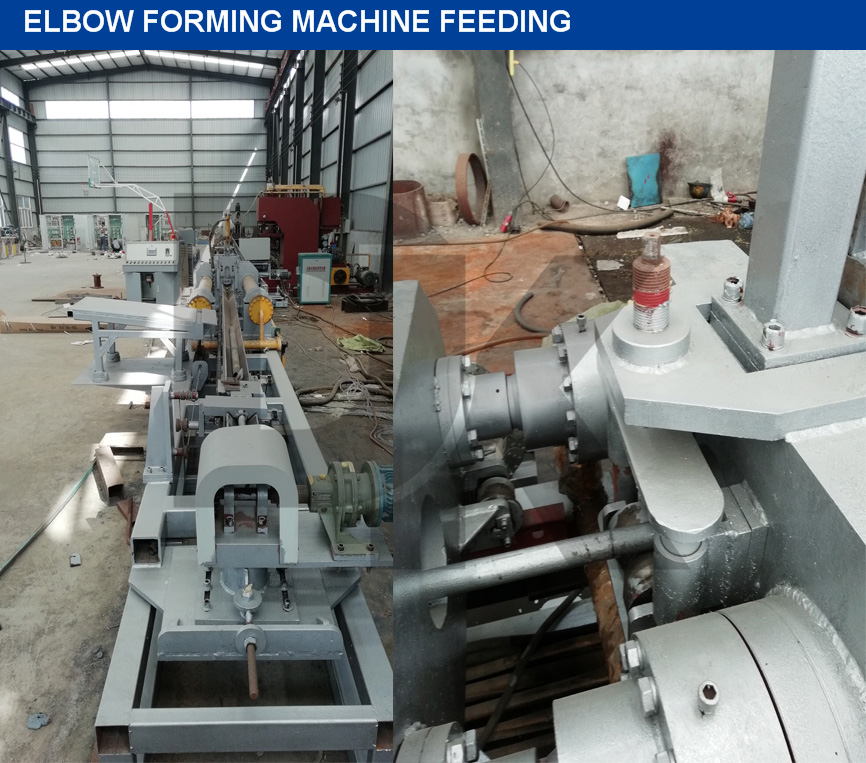

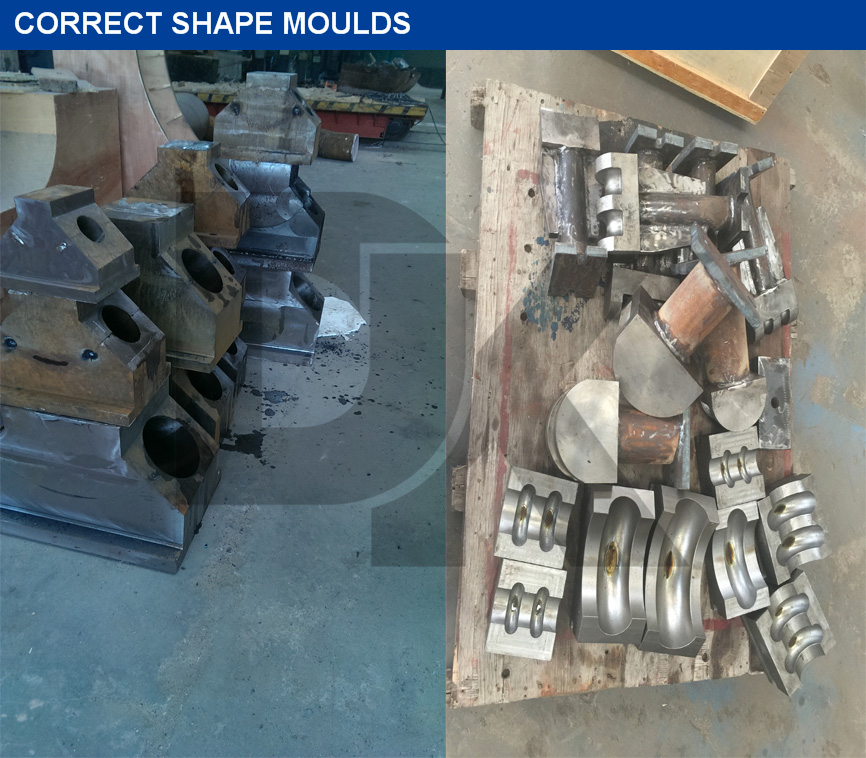

Hot forming elbow machine includes a frame on which an intermediate frequency heater and a hydraulic system are installed, and is characterized in that: a fixing table is fixed at the rear end of the frame, a hole is formed in the center of the fixing table, and several oil cylinders are fixed on the fixing table, the rod cavity and rodless cavity of each oil cylinder are respectively connected with the hydraulic system through pipelines, the push head is connected and fixed with the top of the cylinder rod of each oil cylinder, the center of the push head has a hole, the intermediate frequency heater is connected with the heating ring by a wire, and the heating ring is connected by a wire. The center of the heating ring is on the same line with the hole in the center of the pusher and the center hole of the fixing table, and the core rod with the wedge key hole at the back passes through the heating ring, the hole in the center of the pusher and the hole in the center of the fixing table. After the core rod passes through the wedge key hole at the rear, it is located just behind the center hole of the fixing table. The wedge key is passed through the wedge key hole of the core rod. The produced elbows have the same shape. The movable semicircular card board is composed of upper and lower semicircular cardboards. The upper and lower semicircular cardboards of the movable semicircular cardboard are both installed on the front surface of the pusher and sleeved on the core at the same time. on the rod and leave a gap with the core rod.

| NO. | Model | Elbow Range (mm) | Bending Radius | Thrust (t) | Bending Angle | M.F Power (kw) | Max Working Thrust (t) |

| 1 | DK-EW-114 | 25~114 | 1~2.5D | 50 | 0~135º | 160~200 | 42 |

| 2 | DK -EW-219 | 108~219 | 1~2.5D | 84 | 0~135º | 200~250 | 72 |

| 3 | DK -EW-325 | 108~325 | 1~2.5D | 106 | 0~135º | 300~350 | 91 |

| 4 | DK -EW-426 | 159~426 | 1~2.5D | 160 | 0~135º | 350~400 | 137 |

| 5 | DK -EW-558 | 219~530 | 1~2.5D | 206 | 0~135º | 400~450 | 177 |

| 6 | DK -EW-630 | 325~630 | 1~2.5D | 260 | 0~135º | 450~500 | 220 |

| 7 | DK -EW-720 | 325~720 | 1~2.5D | 300 | 0~135º | 500~600 | 257 |

| 8 | DK -EW-820 | 426~820 | 1~2.5D | 330 | 0~135º | 600~800 | 282 |

| 9 | DK -EW-914 | 426~914 | 1~2.5D | 410 | 0~135º | 600~800 | 351 |

| 10 | DK -EW-1067 | 530~1020 | 1~2.5D | 670 | 0~135º | 1000~1200 | 574 |

| 11 | DK -EW-1220 | 630~1220 | 1~2.5D | 850 | 0~135º | 1000~1200 | 728 |

| 12 | DK-EW-1420 | 720~1420 | 1~2.5D | 1050 | 0~135º | 1200~1500 | 900 |

| Note:1. The machine's technical parameters is based on pipe wall thickness≤20mm. | |||||||

| 2. MAX pipe wall thickness can be 150mm. Machine can be designed according to user's requirements. | |||||||

Add.: Cangzhou City, Hebei Province, China

Tel.: +86 317 8969 768

Mob.: +86 186 3076 4242

Fax: +86 317 8969 768

WhatsApp: +86 186 3076 4242

WeChat: +86 186 3076 4242

Skype: live:manager_11748

E-mail: manager@tyfittingsmachine.com

NAVIGATION