product description

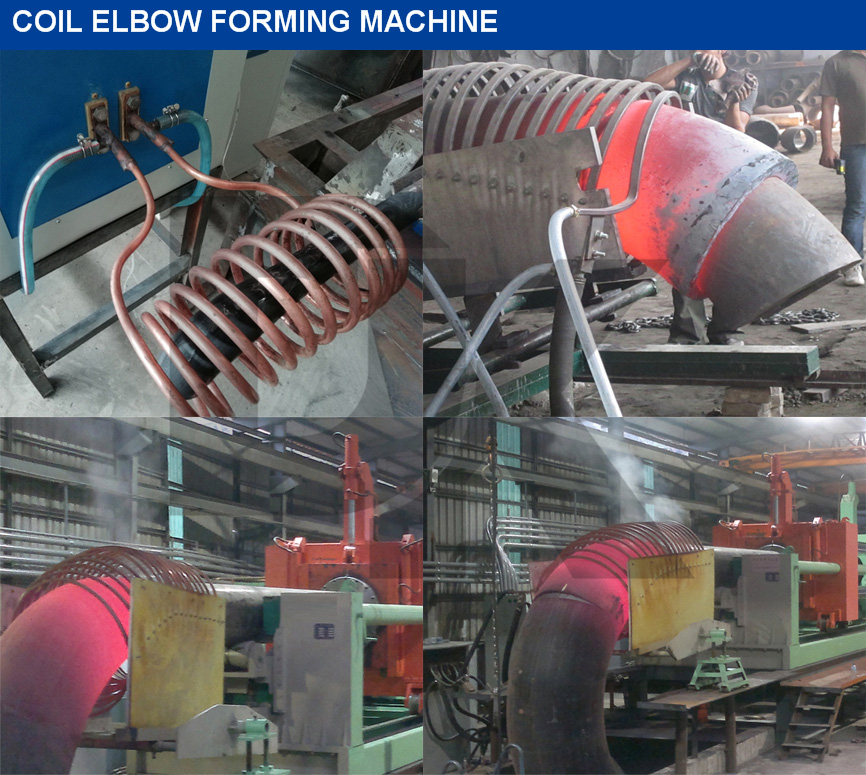

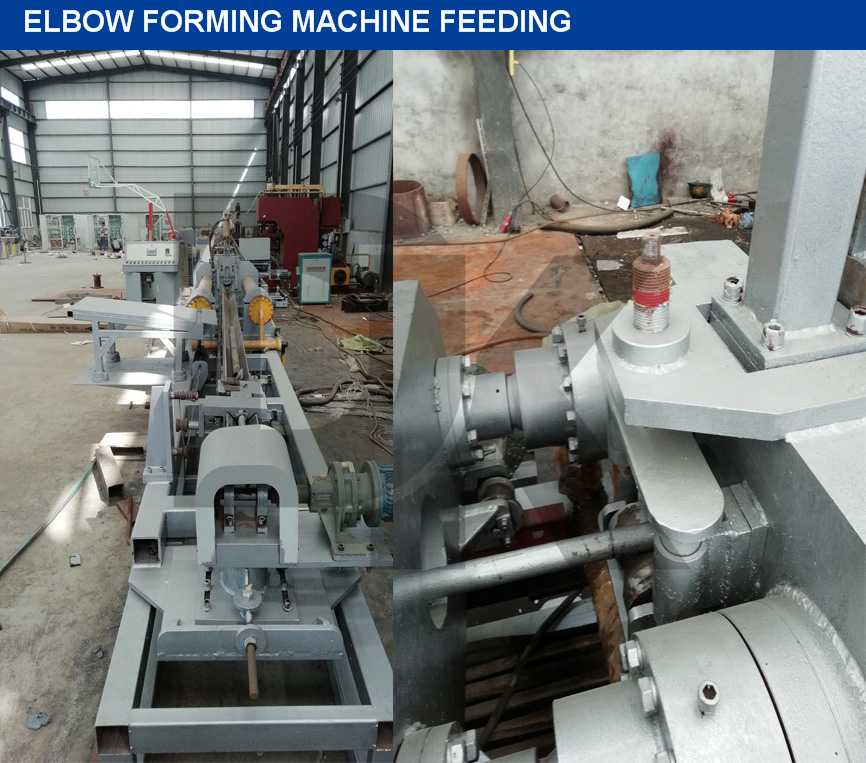

First, the material is hot pushed. The push machine is a horn-shaped core or mandrel, and the mandrel changes from thin to thick. The process of pushing the elbow is a process of expanding the diameter of the belt and bending it. There is a support at the back. The material pipe section penetrates the mandrel, there is an arch frame behind to fix the mandrel, and there is a small car in the middle, some of which are driven by hydraulic drive, some are driven by mechanical transmission, that is, screw drive, and then push the cart forward, and the cart pushes the pipe along the core. The rod moves forward, there is an induction coil outside the mandrel, the tube is heated, heated, and then the trolley pushes the tube down, and one is processed.

Second, in the finishing process, after shot blasting, the iron oxide scale on the inner and outer surfaces of the elbow is removed, and both ends are beveled to facilitate welding.

Third, first select the specifications and propose the pipe material, for example, a 90-degree elbow, through its curvature, it can be calculated how long the material can be processed into a 90-degree elbow, and then cut off with this length as a fixed length.

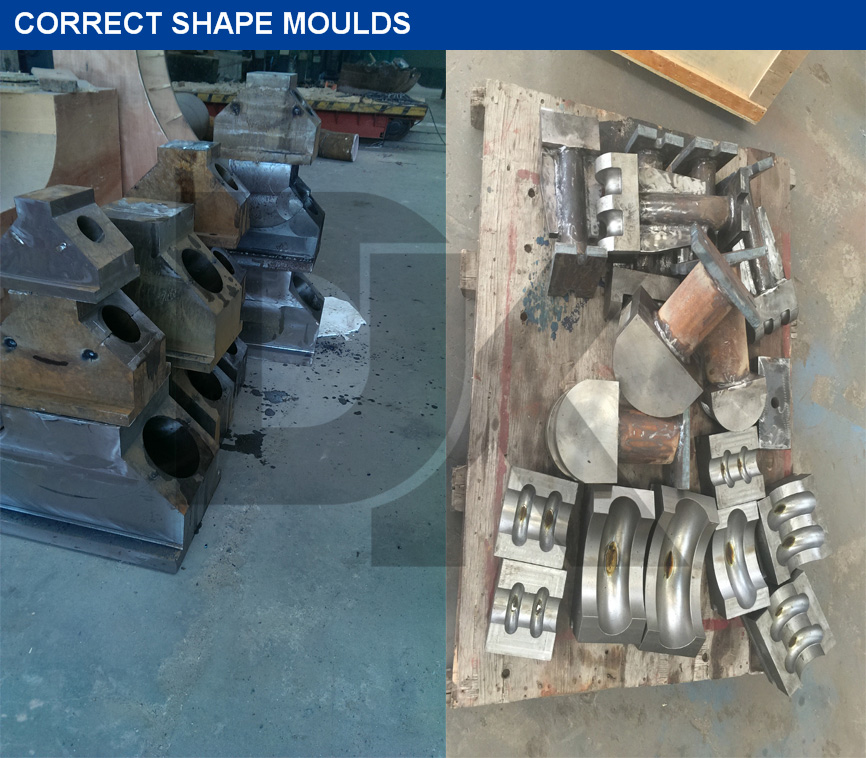

Fourth, after pushing, the elbow should be reshaped in this hot state, because some elbows will be twisted after improper handling, which is not allowed. In addition, after pushing the head, the outer diameter of the front end is generally large, and it needs to be shaped by a shaping die. The shaping die is actually a press, and there must be a set of die, two semi-circular arcs, one on the top and one on the bottom. The outer diameter after shaping has reached the size of the finished product.

| NO. | Model | Elbow Range (mm) | Bending Radius | Thrust (t) | Bending Angle | M.F Power (kw) | Max Working Thrust (t) |

| 1 | DK-EW-114 | 25~114 | 1~2.5D | 50 | 0~135º | 160~200 | 42 |

| 2 | DK -EW-219 | 108~219 | 1~2.5D | 84 | 0~135º | 200~250 | 72 |

| 3 | DK -EW-325 | 108~325 | 1~2.5D | 106 | 0~135º | 300~350 | 91 |

| 4 | DK -EW-426 | 159~426 | 1~2.5D | 160 | 0~135º | 350~400 | 137 |

| 5 | DK -EW-558 | 219~530 | 1~2.5D | 206 | 0~135º | 400~450 | 177 |

| 6 | DK -EW-630 | 325~630 | 1~2.5D | 260 | 0~135º | 450~500 | 220 |

| 7 | DK -EW-720 | 325~720 | 1~2.5D | 300 | 0~135º | 500~600 | 257 |

| 8 | DK -EW-820 | 426~820 | 1~2.5D | 330 | 0~135º | 600~800 | 282 |

| 9 | DK -EW-914 | 426~914 | 1~2.5D | 410 | 0~135º | 600~800 | 351 |

| 10 | DK -EW-1067 | 530~1020 | 1~2.5D | 670 | 0~135º | 1000~1200 | 574 |

| 11 | DK -EW-1220 | 630~1220 | 1~2.5D | 850 | 0~135º | 1000~1200 | 728 |

| 12 | DK-EW-1420 | 720~1420 | 1~2.5D | 1050 | 0~135º | 1200~1500 | 900 |

| Note:1. The machine's technical parameters is based on pipe wall thickness≤20mm. | |||||||

| 2. MAX pipe wall thickness can be 150mm. Machine can be designed according to user's requirements. | |||||||

Add.: Cangzhou City, Hebei Province, China

Tel.: +86 317 8969 768

Mob.: +86 186 3076 4242

Fax: +86 317 8969 768

WhatsApp: +86 186 3076 4242

WeChat: +86 186 3076 4242

Skype: live:manager_11748

E-mail: manager@tyfittingsmachine.com

NAVIGATION